About Us

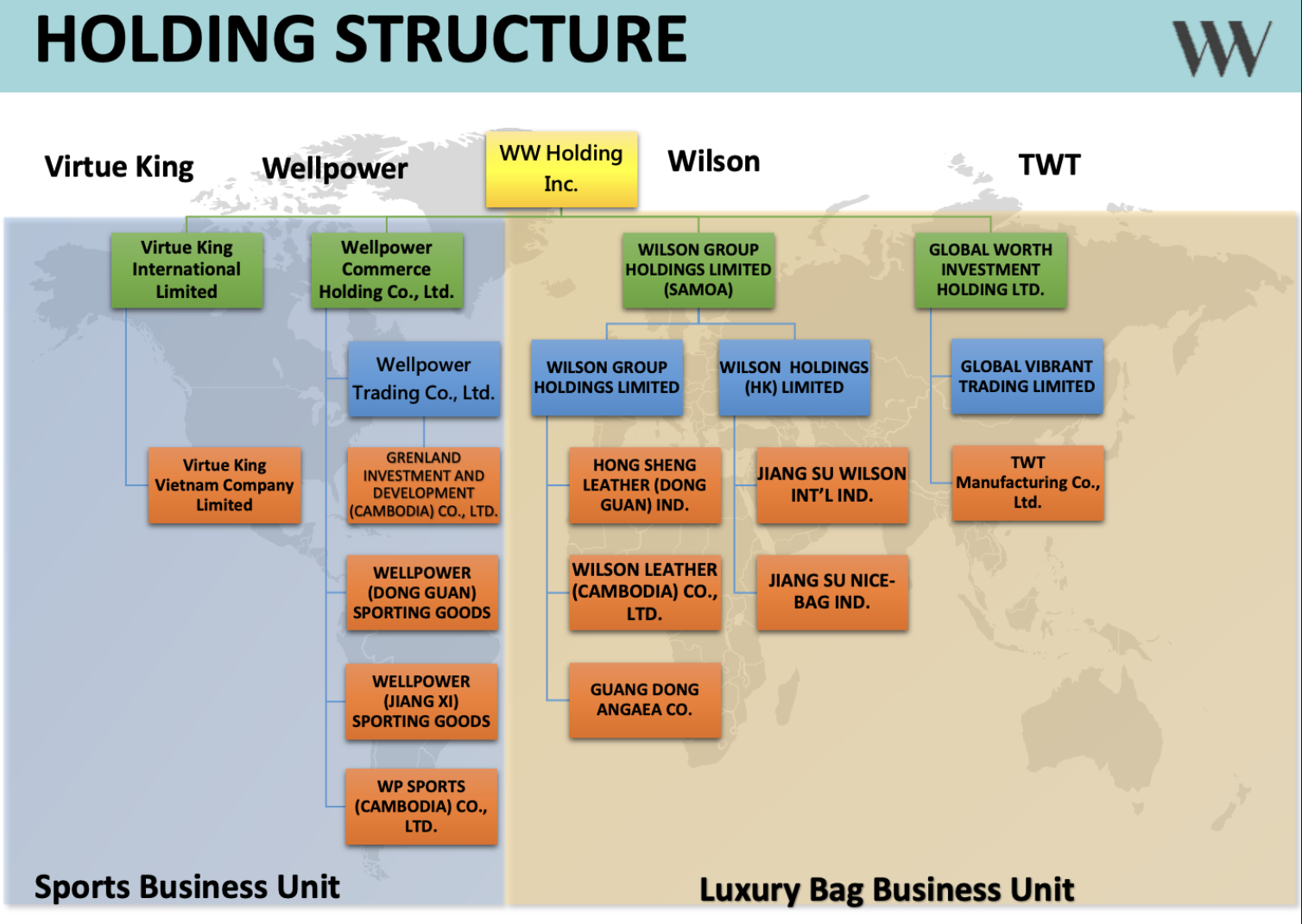

WW Holding consists of 4 companies:

Wilson Bag—Luxury bags, business bags, sports bags

Wellpower—Sports equipment and protection gears, medical protection gears

Virtue King—Golf bags, sports bags

TWT—Luggage, business bags

Production sites in China, Vietnam, Thailand, Cambodia. IPO in Taiwan and listed on TWSE on 2016.

Stock code: 8442

About Us

WW Holding consists of 4 companies:

Wilson Bag—Luxury bags, business bags, sports bags

Wellpower—Sports equipment and protection gears, medical protection gears

Virtue King—Golf bags, sports bags

TWT—Luggage, business bags

Production sites in China, Vietnam, Thailand, Cambodia. IPO in Taiwan and listed on TWSE on 2016.

Stock code: 8442

Company Locations

Company Locations

The head quarter of WW Holding is located in New Taipei City, Taiwan. Each of its subsidiaries has solid production capabilities, complete factory equipment, and skilled employees, and is equipped with digital management systems such as PLM, ERP, MES, and Kanban management, as well as experienced technical transfer centers to achieve digitalization and management of production. Intelligentization, while greatly improving customer satisfaction, also drives the company’s continuous growth and maximizes shareholder returns.

Factory information

Wilson Bags, Dongguan, Guangdong

Development Center

Wellpower (Jiangxi) Sporting Goods Co., Ltd.

Ganzhou City, Jiangxi

Wilson Leather (Jiangsu) Co. Ltd.

Huai-an, Jiangsu

Taiwan Headquarter

Dajia Taichung Skill Transfer Center

Virtue King Vietnam Co., Ltd.

Binh Duong, Vietnam

Wilson Leather (Cambodia) Co., Ltd.

Phnom Penh, Cambodia

TWT Manufacturing Co., Ltd.

Chon Buri, Thailand

The Strategy of international development

in the spirit and

soul of Taiwan

The Strategy of international development

in the spirit and

soul of Taiwan

Formerly WW Holding Inc. was founded in 2009, formerly known as Wellpower Sporting Goods Co., Limited. WW Holding Co. Ltd. merged with Wilson Group Holdings Limited in 2014 and changed its title as WW Holding. Under the leadership of Chairman Hung Yung-yu, the Company is engaged in two major areas of operation, namely, fashion bags (Wilson Group Holdings Limited and sports equipment and accessories (Wellpower Sporting Goods Co., Limited). These two operations supply products in their respective areas internationally. Like many other business in international development, the Company makes positive effort to expand its production capacity in Southeast Asia with Vietnam and Thailand in particular. The Company is incorporated in the British Cayman Islands, which makes it a foreign company under the laws of Taiwan. However, the key management team of the Company is from Taiwan, and that makes it a Taiwanese company spiritually. The operation of the Company in Taiwan aims at waking up the talents in Taiwan to carry on the spirit of taking sports as recreation and trend and demonstrate the strength of Taiwanese enterprises in the world.

- 2001

- 2004

- 2006

- 2011

- 2012

- 2013

- 2014

- 2014

- 2015

- 2016

- 2017

- 2017

- 2020

Sample development and design team

The sample development department is actively joining the digital process, which can more effectively and accurately assist customer designers to materialize design drawings. After the brand designers complete the design drawings in France, Italy, the United States and other European and American countries, the sample production team of WW Holding will analyze the design drawings to make the design drawings materialized, supplemented by front-end technology and strict quality control to work closely with designers. The complete material supply chain of WW Holding is provided to provide a fast and direct process to meet the requirements of customers.

Skill Transfer Center

Strong skill transfer center is to decompose the parts of bags that will be mass-produced, break down a physical bag into individual pieces, and then make paper grids to ensure that the production process of each piece is of the same size and standardized. The production process, through changes in the system structure, personnel organization, operation mode, and market supply and demand, enables the production system to quickly adapt to the changing needs of users, and can streamline all useless and redundant steps in the production process, and finally achieve the best results in all aspects of production, including market supply and marketing. This allows the factory to smoothly mass produce every bag from scratch.

Dedicated laboratory and global repair center

Our laboratory is certified by SGS. The laboratory tests include moisture resistance (simulating the humidity in the container will not make the leather moldy and rotten), water repellency (water splashing test for water repellent series bags), and color test (The back and forth friction test of the leather fabric will not fade easily), anti-gravity (the handle or strap will not break easily after the bag is loaded with heavy objects), zipper durability (the back and forth test will not be easily damaged) and other test equipment. Strict quality control is carried out from the raw material end to the finished product end.

Group Organization Chart