Smart Production

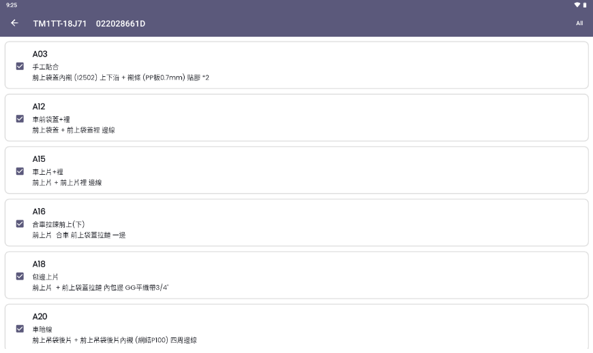

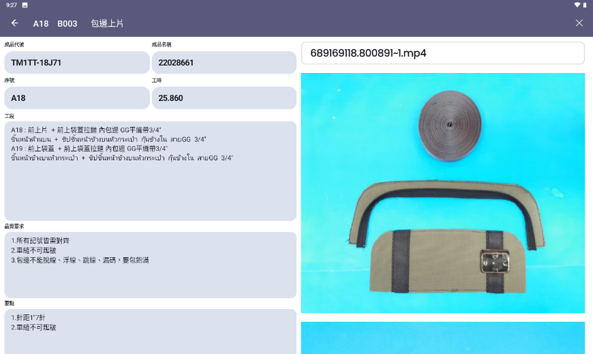

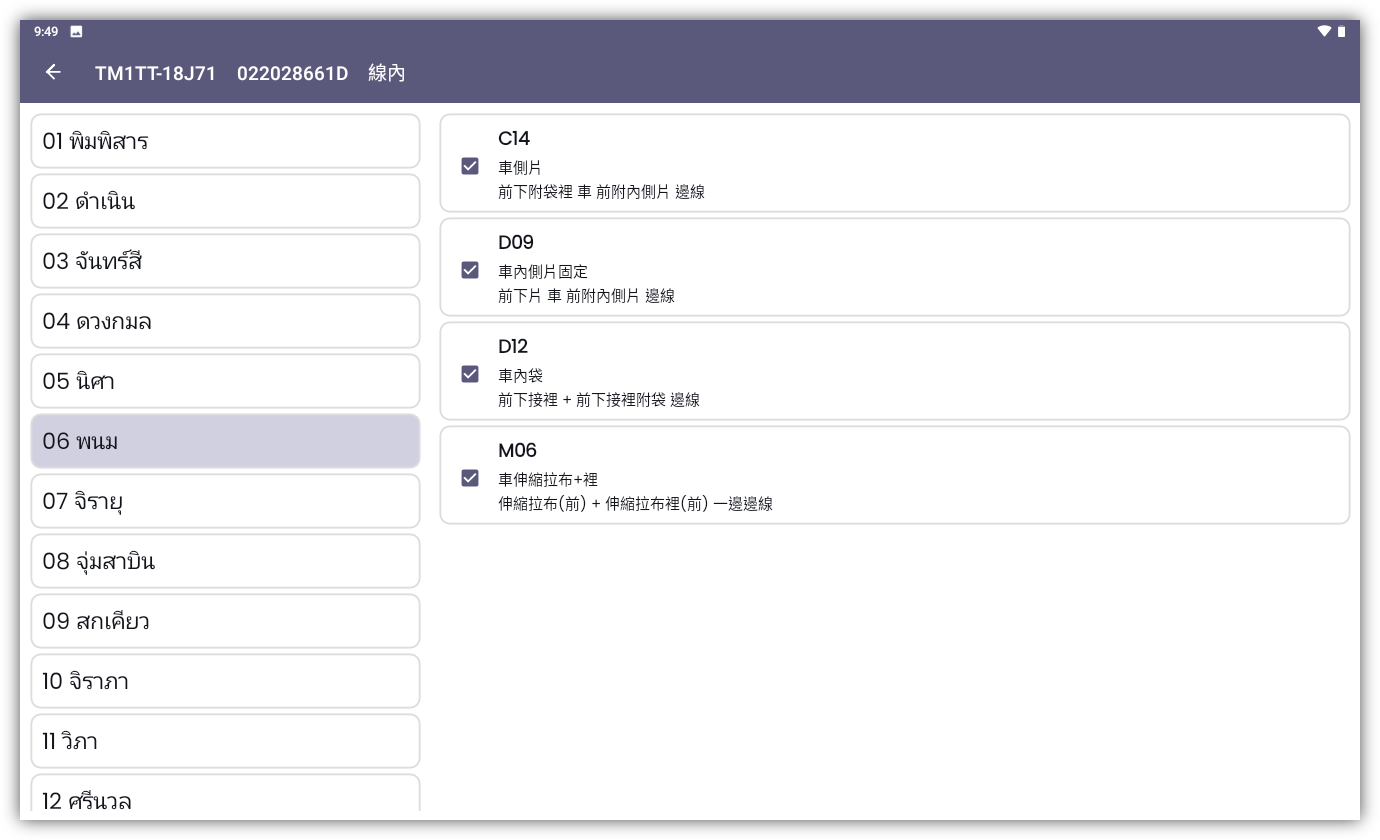

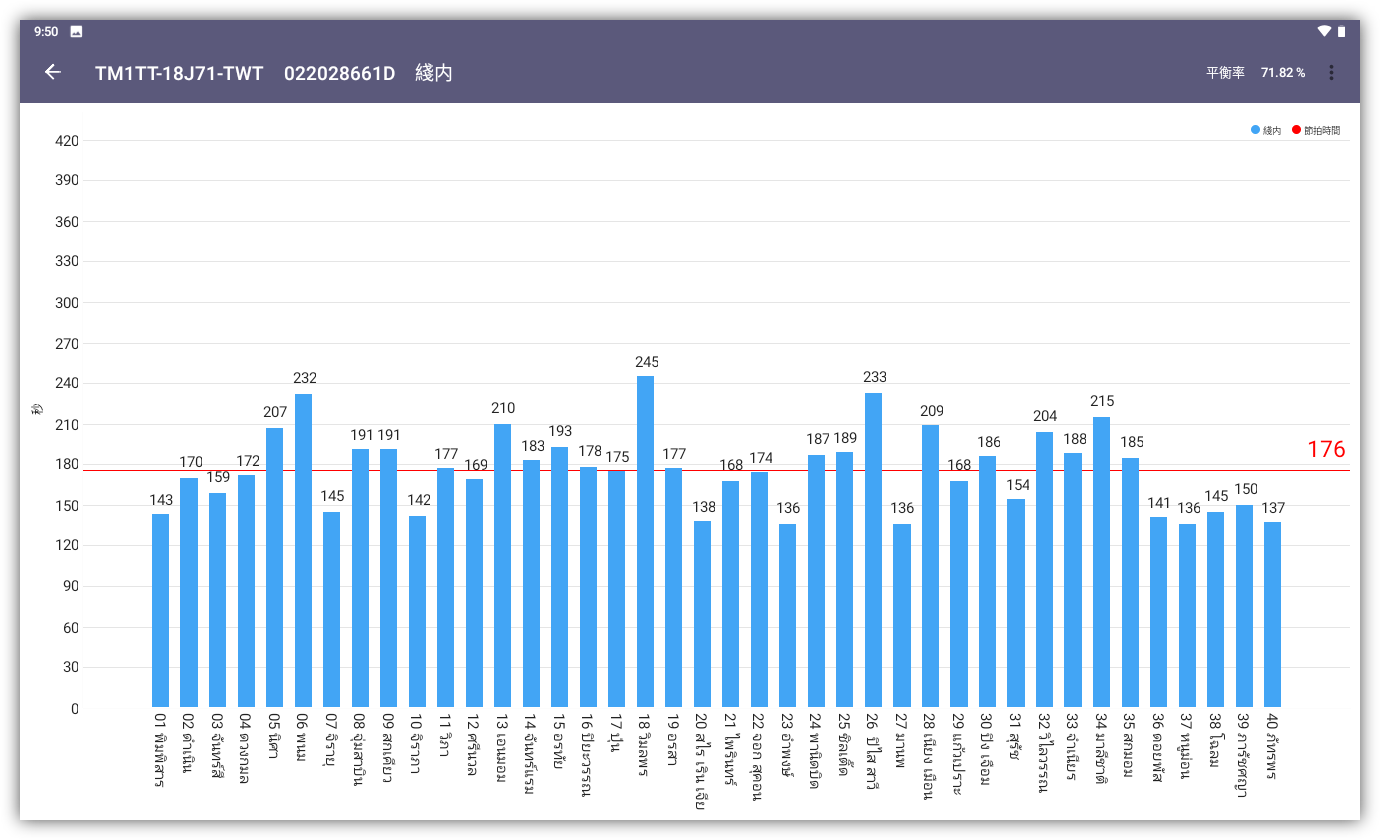

We continue to implement systems such as PLM (Product Lifecycle Management), MES (Manufacturing Execution System), WMS (Warehouse Management System) and Kanban System. Production flow digitization will help us reach the goals of quality, safety, efficiency, cost and on-time delivery.

Smart Production

We continue to implement systems such as PLM (Product Lifecycle Management), MES (Manufacturing Execution System), WMS (Warehouse Management System) and Kanban System. Production flow digitization will help us reach the goals of quality, safety, efficiency, cost and on-time delivery.

3D Sample Process

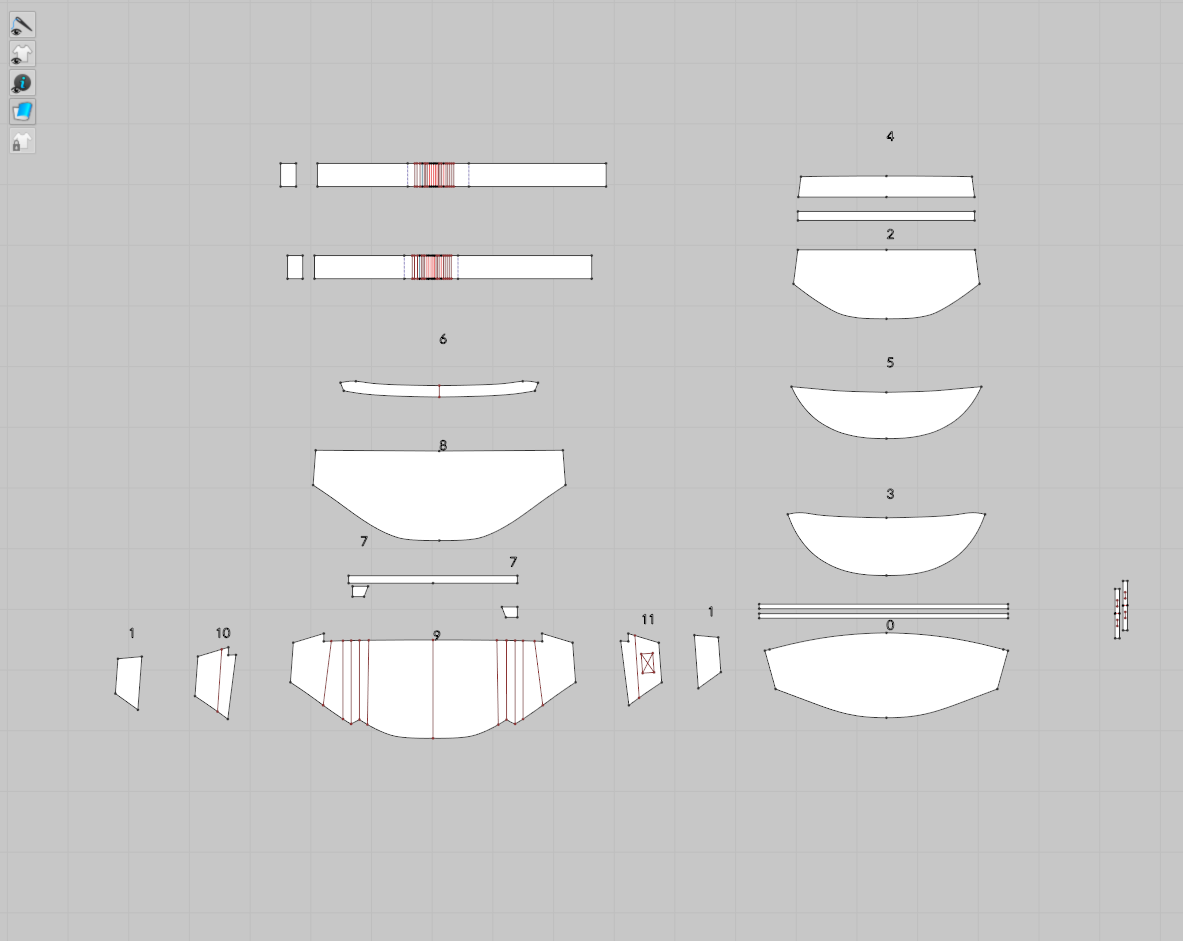

Pattern Making

The pattern maker makes pattern pieces according to the design drawing provided by the customer.

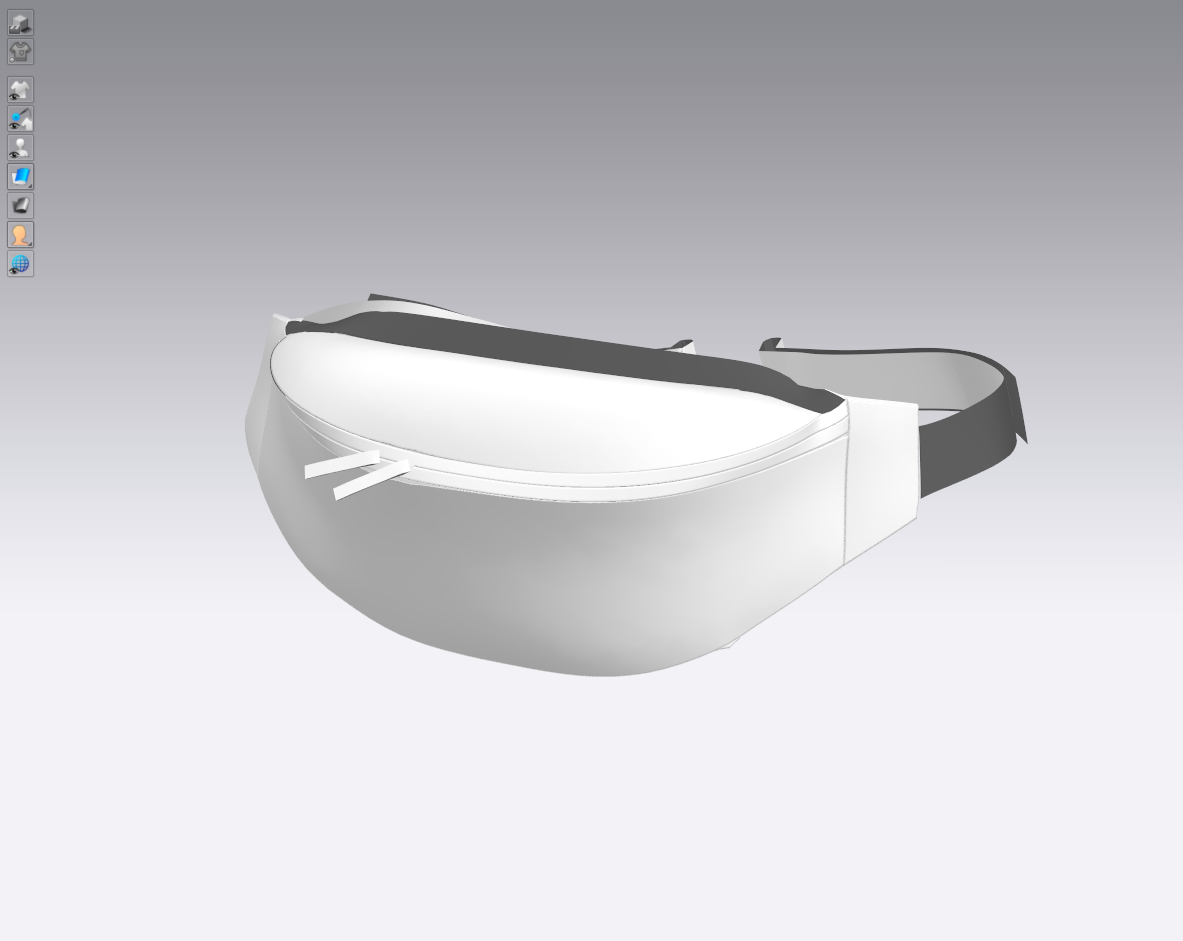

CLO White Model

Use CLO to make the basic shape and structure of the bag.

3D White Model

Use 3D software to make the details of the bag.

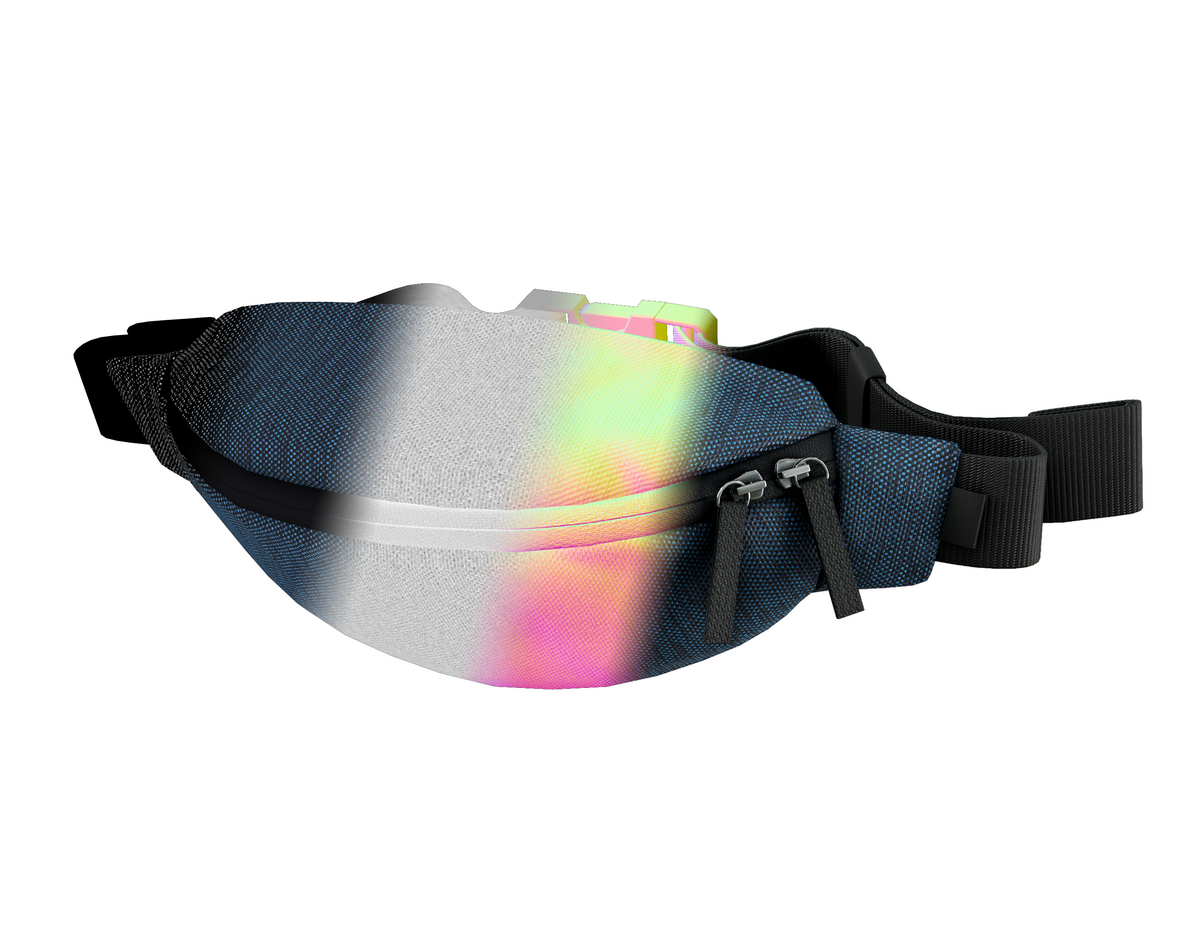

Texture

Make a digital texture map of the bag. Materials and colors can be changed easily.

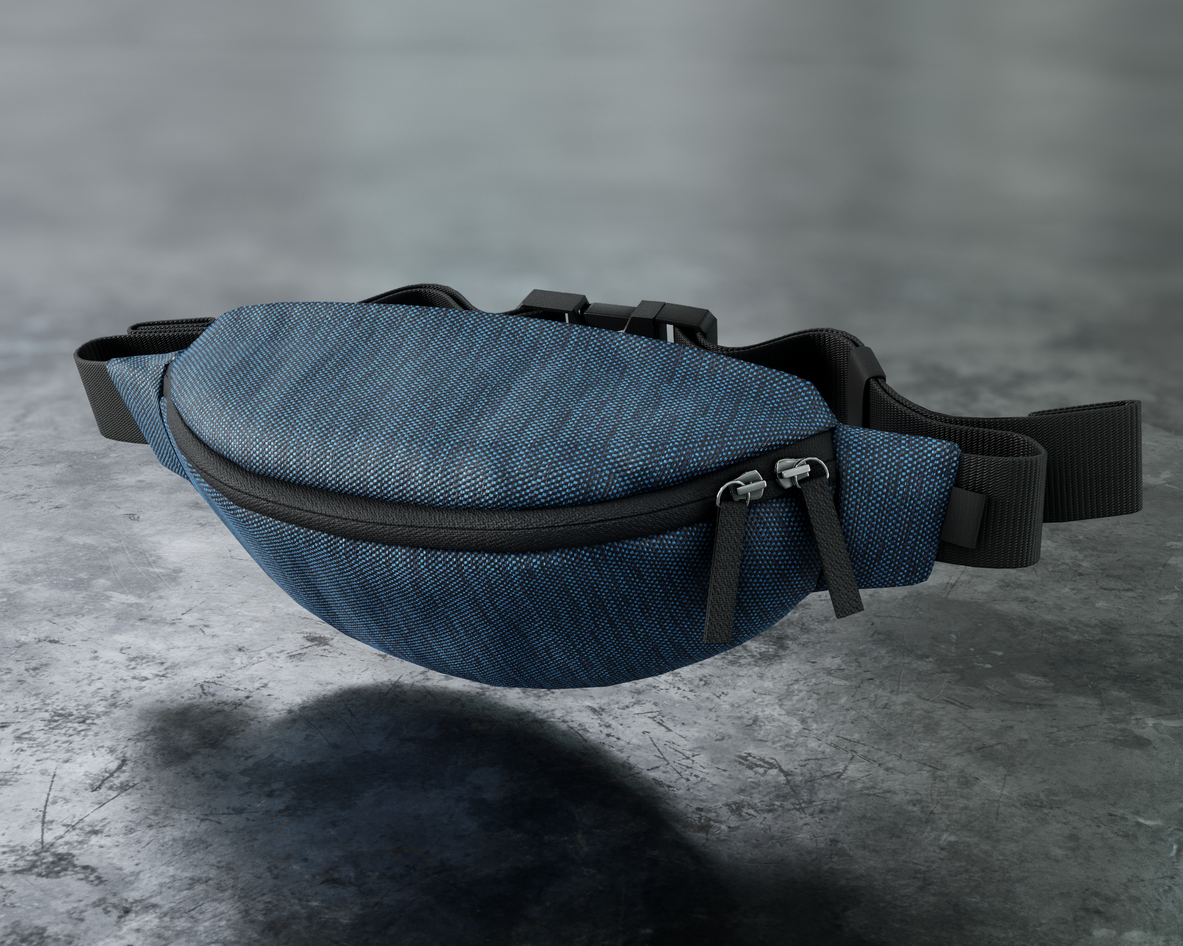

Light/Render

Add lighting to render a realistic picture and the actual sample can be previewed.

Based on designers’ 2D drawings, 3D sampling can provide instant modification and adjustment. Communication with 3D visual samples can greatly improve efficiency at the product development stage. By eliminating a few physical samples, actual materials and transportation costs can be saved, which is also more friendly to earth. 3D sampling shortens the entire development process and speeds up time to market.